Project Analysis No. 3

Market Sector : Tooling Manufacturing

Type of Machines : Centerless Grinders

Problem : Wheel wear & thermal expansion.

Form of Contact : Using the contact form on cool-grind.com.

Solution : Replace OEM coolant nozzles with Cool-Grind’s Centerless Coolant Nozzles.

A tooling manufacturer was having troubles with thermal expansion during the grinding process. They had made the decision to switch from a water-based coolant to an oil-based coolant, in an attempt to reduce thermal expansion. After switching to an oil based coolant, they found problems with getting coolant into the grind with their OEM coolant delivery system.

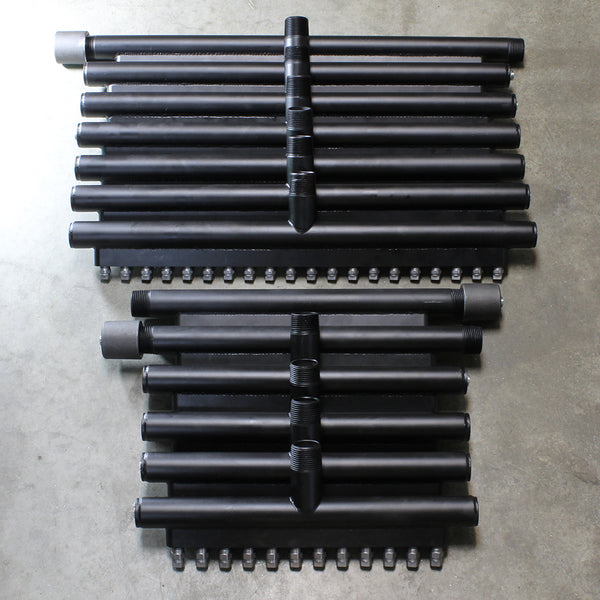

The tooling manufacturer realized that they needed help from an external source. After several recomendations, they decided to contact Cool-Grind via our website. After looking through cool-grind.com, the obvious choice for them was the Centerless Coolant Nozzle. Cool-Grind contacted the manufacturer via a phone call and then shortly recieved a PO for a 12” End-Feed Centerless Coolant Nozzle. This nozzle was built and shipped the next day.

1 week later Cool-Grind recieves a PO for 8 more centerless nozzles. The tooling manufacturing was finding great improvement in their grinding process after installing the 12” Centerless Coolant Nozzle. The increased pressure from the Cool-Grind coolant nozzles was able to break through the air barrier and allow the oil coolant to get into the grind. This dramatically reduced the thermal expansion, and subsequent size error. Cool-Grind built and shipped the 8 additional Centerless Coolant Nozzles 3 days later.

“ Cool-Grind’s standing is golden and I have a feeling you will be seeing more of this. ” - Tooling Manufacturing Buyer

The buyer wasn’t wrong, 3 weeks later Cool-Grind recieved a additional PO for 13 more Centerless Coolant Nozzles. A total of 22 Centerless Coolant Nozzles for this tooling manufacturer. I think it’s safe to say, they were very pleased with the product.

- A buyer contacts Cool-Grind via the contact form on cool-grind.com. Message reads, “I need some one to call me right away please.”

- Cool-Grind contacts buyer, and learns they are in need of a Centerless Coolant Nozzle ASAP. After confirming pricing and delivery, Cool-Grind recieves a PO for a 12” End-Feed Centerless Coolant Nozzle.

Wednesday, April 11, 2018

- Cool-Grind builds and ships 12” End Feed Centerless Coolant Nozzle.

Monday, April 16, 2018

- Cool-Grind receives a new PO for 8 Centerless Coolant Nozzles (1 X 12” End-Feed Centerless Coolant Nozzle, 4 x 12” Tee-Feed Centerless Coolant Nozzle, 1 x 20” End-Feed Centerless Coolant Nozzle, and 2 x 20” Tee-Feed Centerless Coolant Nozzle).

Wednesday, April 18, 2018

- Cool-Grind builds and ships all 8 Centerless Coolant Nozzles.

Monday, May 7, 2018

- Cool-Grind receives a new PO for 13 Centerless Coolant Nozzles (2 X 12” End-Feed Centerless Coolant Nozzle, 4 x 12” Tee-Feed Centerless Coolant Nozzle, 1 x 20” End-Feed Centerless Coolant Nozzle, and 6 x 20” Tee-Feed Centerless Coolant Nozzle).

Monday, May 14, 2018

- Cool-Grind builds and ships all 13 Centerless Coolant Nozzles.