Project Analysis No. 1

Market Sector : Aerospace

Type of Machine : Kellenberger 1000

Problem : Grinding scratches

Form of Contact : Email from recommendation

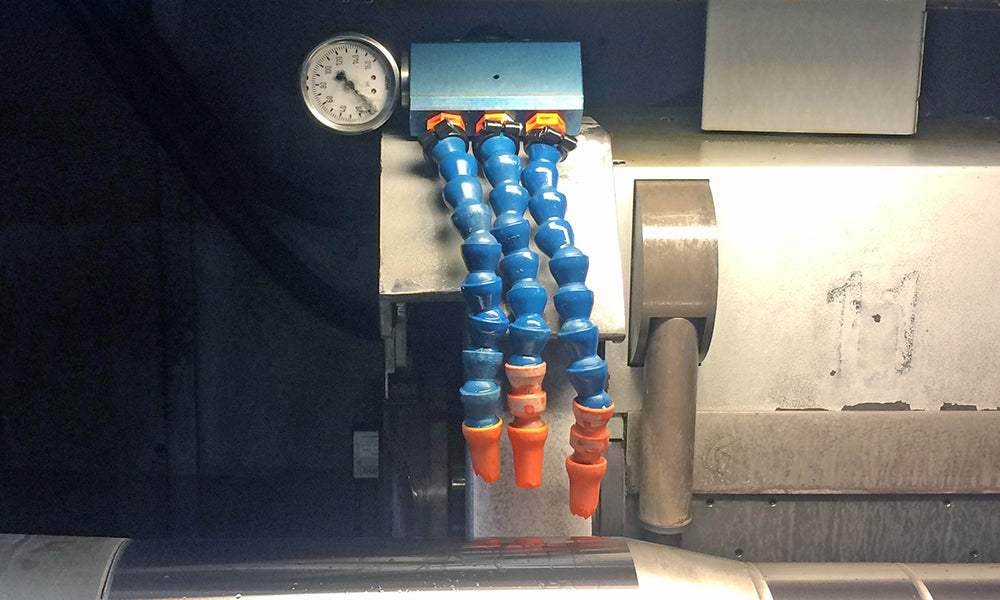

Solution : Replace OEM coolant nozzles with Cool-Grind’s Grind-Loc System

A process engineer from an aerospace manufacturer contacted Cool-Grind via email, he was having problems with scratches on the surface of his parts. Cool-Grind visited his facility to take a closer look at the part and his grinding set-up. After a quick analysis, it was clear that he needed a new coolant solution. The machine had a flood nozzle coolant delivery, which did not provide the precision he needed for a clean surface grind. Cool-Grind figured out the nozzles that were required for his machine, and left with a guarantee that he would have the correct nozzle set-up and installation within a week.

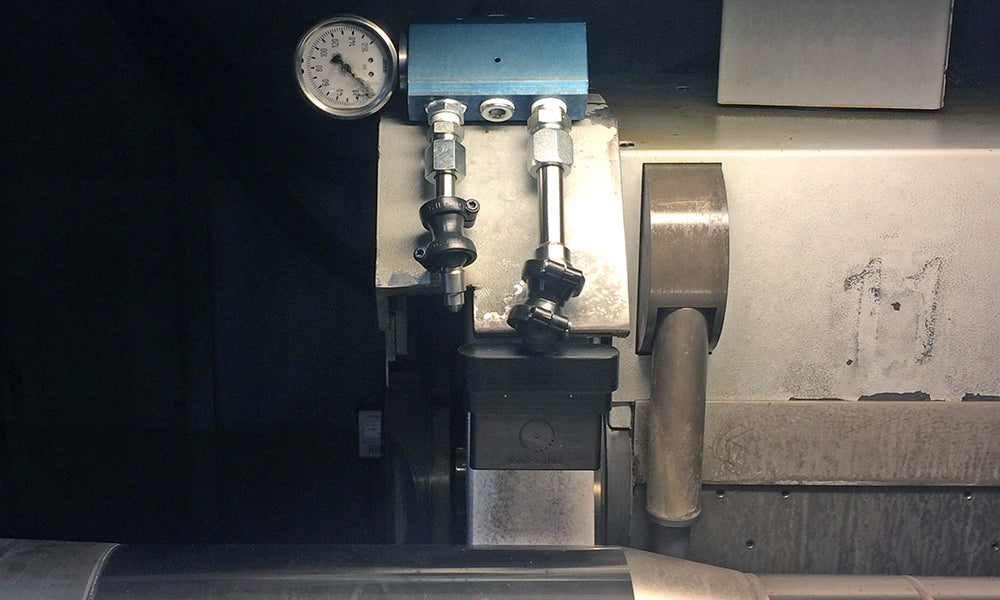

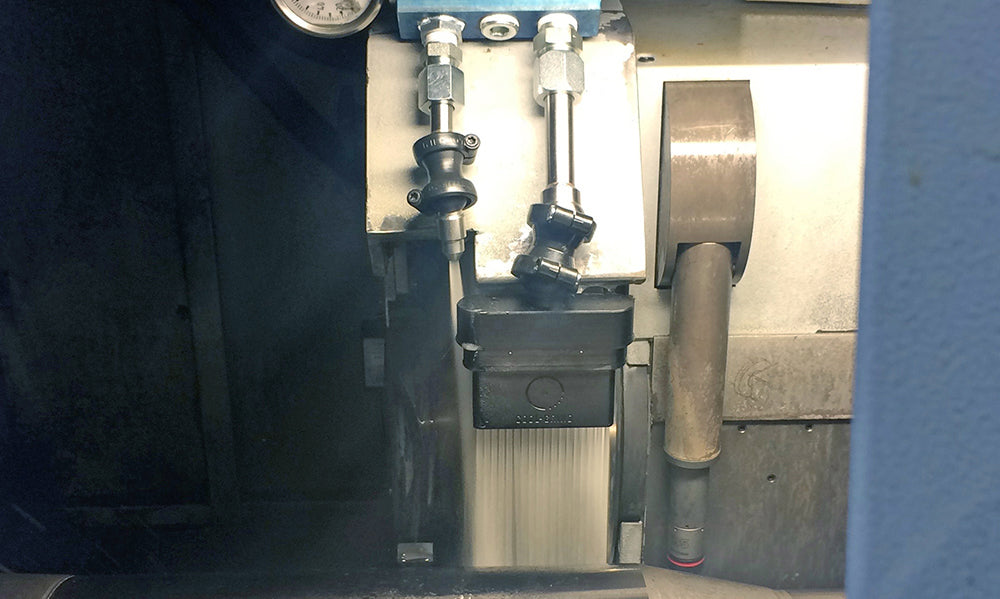

4 Days later, Cool-Grind came back with a 2” Multi-Jet Ultra-Wide Flat Swivel Coolant Nozzle and a 1/2 Standard Round Swivel Coolant Nozzle with Double Swivel Coupling. For linear adjustment 2 of our Short Extension Tubes with Ball were provided, and for mounting we used 2 of our Collet Fittings. Cool-Grind removed the old coolant system and installed the new Cool-Grind Grind-Loc System on his machine. The thread on the existing manifold were to large for our Collet Fittings, in order to make them fit the Reducer Bush was used to get the necessary thread we needed. The ultra wide nozzle gave him the coverage he needed on the grinding wheel and the Round nozzle was for side of the grinding wheel at the point of contact. To ensure that the coolant nozzles were pointing directly at the point of contact, Cool-Grind used their Miniature Laser Aligning System for dry alignment.

After the machine was used for 2 days, the process engineer contact Cool-Grind. He was very pleased with the results, and he paid Cool-Grind for the parts that were provided. The total investment to solve his grinding problem was only $228. Cool-Grind plans on working with this client again to fit nozzles on his other grinding machines.