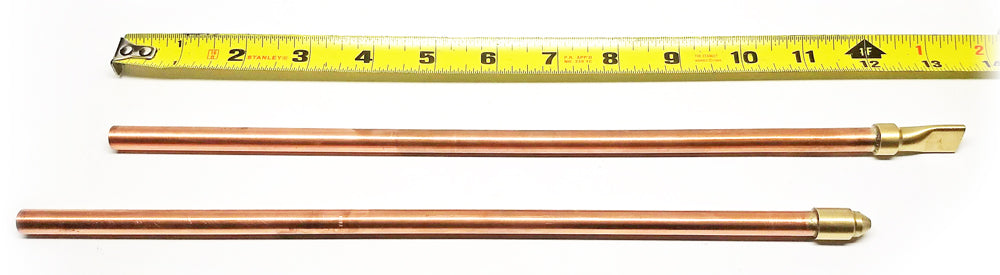

Copper Tube Nozzles

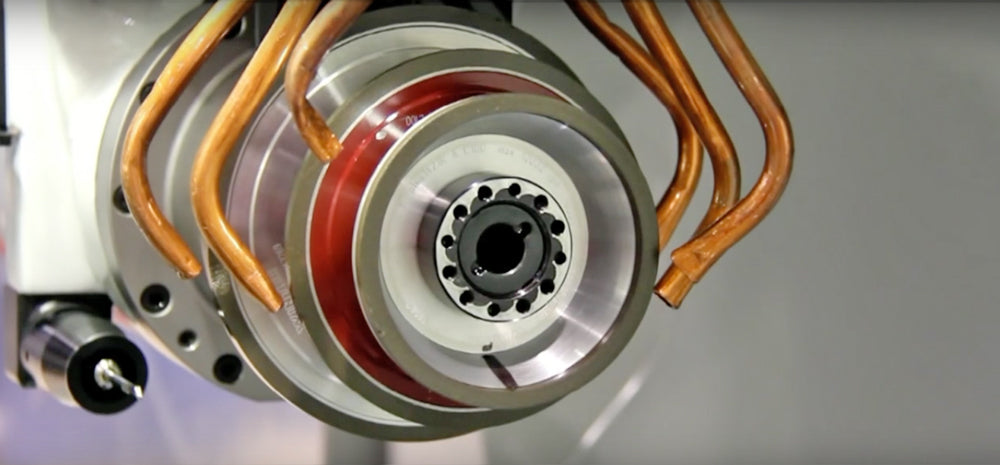

Photo details: Straight Cut Copper Tube with 14 Bar & 140 LPM

Some Problems with Open Metal Tubes

- Dispersed jet, and air entrainment, especially due to cutting burrs

- Crushing end of tube to create increased pressure and wider jet can give even more dispersed jet

- Adjusted by bending, but will fatigue after several attempts

- Jet aims changes when coolant flows, requires bend compensation

- Need to be placed close to wheel to be effective, but then gets damaged

- Rotation of tube in compression fitting changes aim, unless retightened

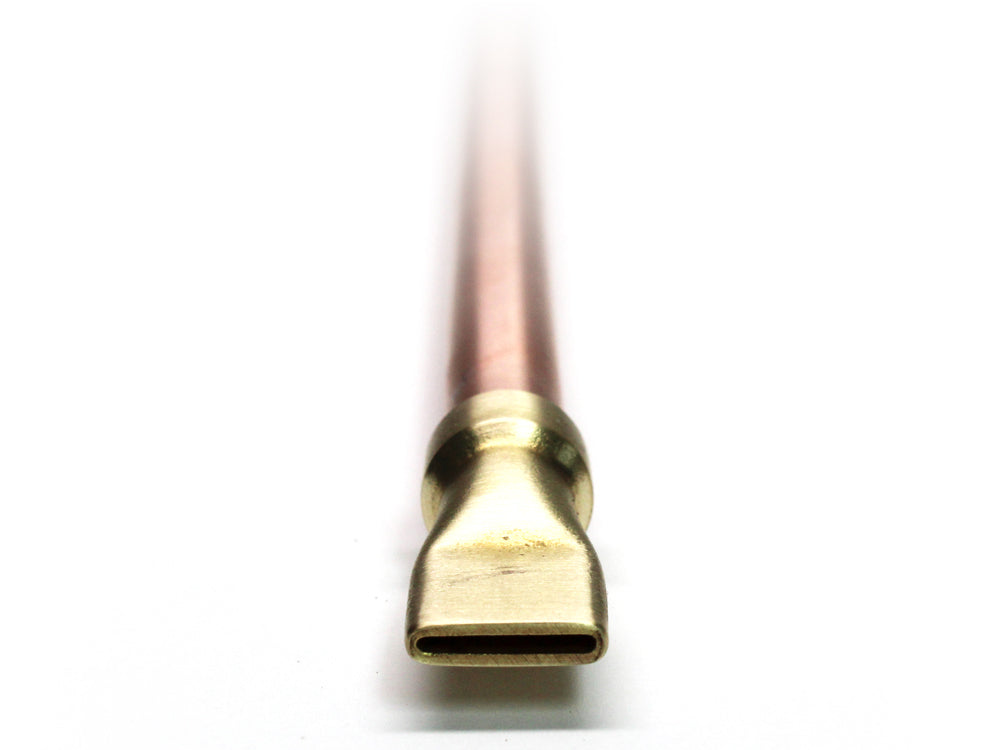

Photo details: Crushing attempt on copper tube

Cool-Grind Solder-Fit Copper Nozzles

Flat Solder-Fit Jet

Flat Solder-Fit Jet Round Solder-Fit Jet

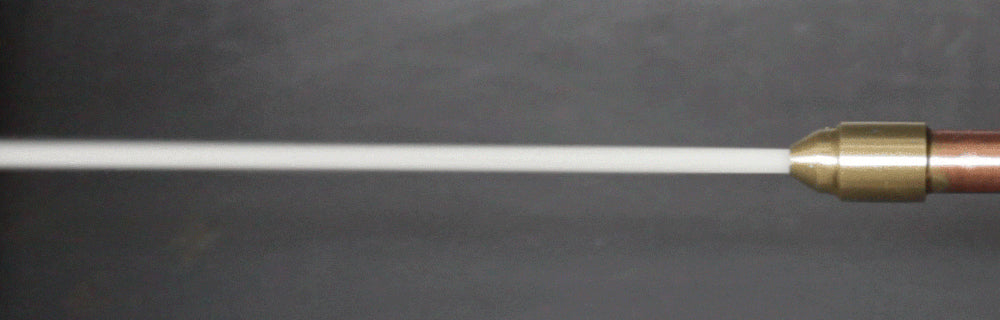

Round Solder-Fit Jet

- Cool-Grind can supply convenient pre-soldered brass on copper nozzle for greatly improved coolant delivery, much reduced flowrate, and higher jet speed.

- Benefits include longer corner retention, cooler grinding, faster throughput, and more tools added to auto-loader.

- The benefits when grinding steel tools are even greater