Hypo-Grind Nozzles

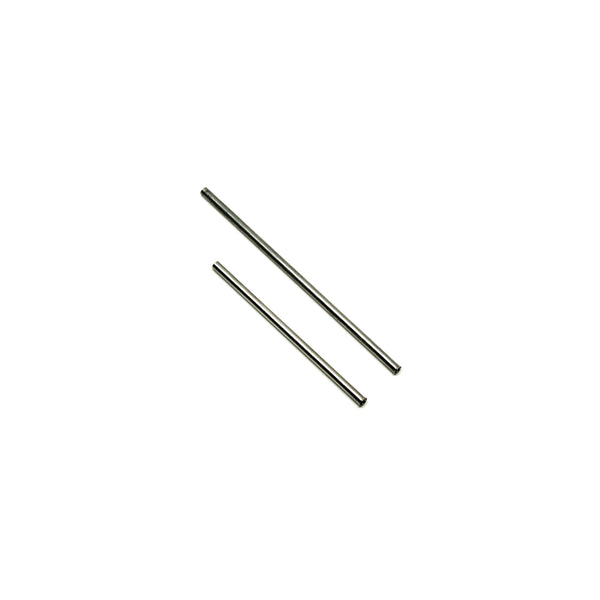

Needle nozzles were pioneered by Aachen University, Germany, in the 1990s. The nozzles use an array of small diameter tubes, fixed to a chamber or endplate, configured to the shape of the grinding wheel Whilst it has been shown that the flow from a straight tube can be mildly disturbed, the favorable length to diameter ratio of the straight tube in the needle nozzle system acts as a flow stabilizer, minimizing dispersion. Typical needle lengths are 2, 3, and 4 inches long.

Hypo-Grind needle nozzle system is based on a stainless steel tube size of 0.106” ID and 0.134” OD. The proximity of adjacent needles is typically 0.167” spacing, or 6 needles per inch. As an example, at a pressure of 100 psi (7 bar) each needle will flow 3 GPM (11 LPM) of water-based coolant, representing a maximum specific flowrate of 18 GPM per inch (2.7 LPM per millimeter). At lower pressure the specific flowrate will be less.

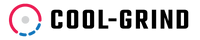

The Hypo-Grind nozzle system is available in either a fixed needle swivel nozzle, fixed needle chamber nozzle (straight or profiled), or re-configurable needle chamber nozzle (Flex). The fixed nozzle chambers are made to order. Both types of chamber nozzles have replaceable endplates that allow the jet profile to be changed to suit the application.