Project Analysis No. 2

Company Name : Aggressive Grinding Services, Inc.

Market Sector : Manufacturing

Type of Machines : Kellenberger Vario OD Grinder, Okuma ID & OD Grinder, Usach OD/ID Grinder

Problem : Thermal damage & high wheel wear when grinding at high removal rates.

Form of Contact : Phone call from owner from internet search.

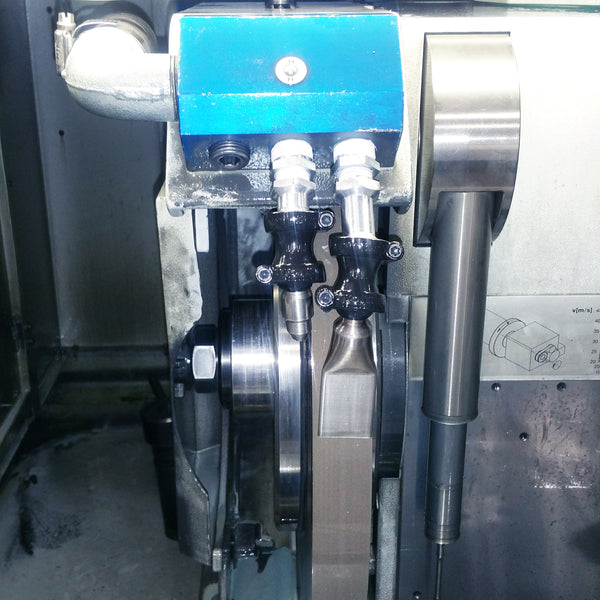

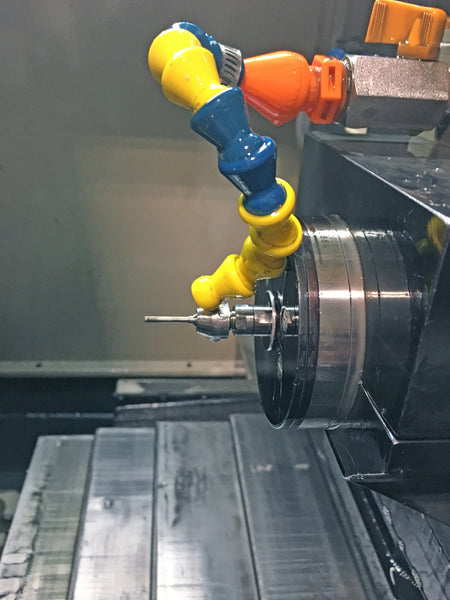

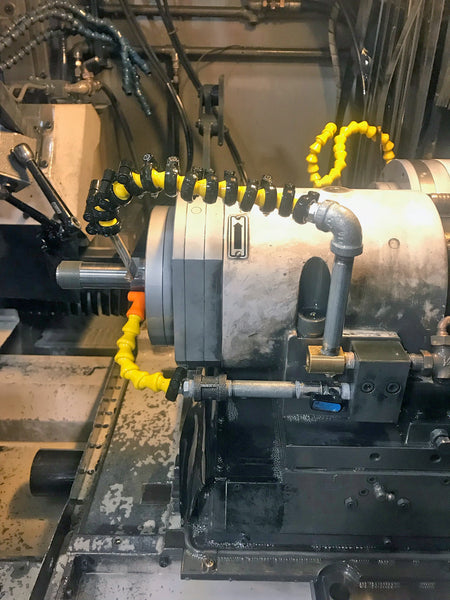

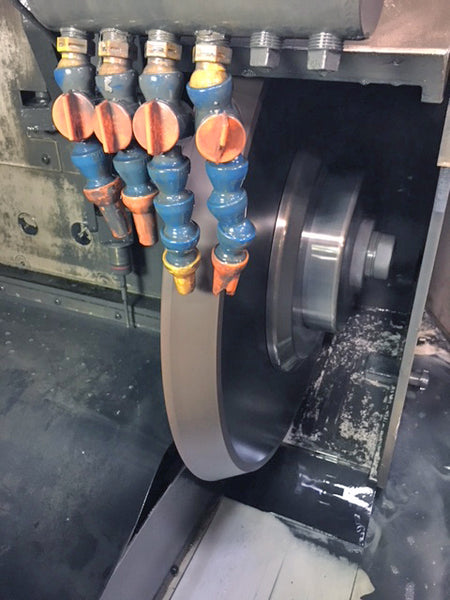

Solution : Replace OEM coolant nozzles with Cool-Grind’s Grind-Loc System.

Due to high demand, Aggressive Grinding Services decided to increase their material removal rates. Unfortunately the OEM coolant system was not able to keep up with this rate. They were experiencing a considerable amount of thermal damage & high wheel wear when grinding. After an internet search, Aggressive Grinding Services found Cool-Grind. They contacted us via a phone call, and decided to invest $2,000 to bring Dr. Cool to their 34,000 square foot facility to establish a solution.

After understanding what machines they were having problems with, Dr. Cool knew what nozzles could help and brought these products to their facility. During his productive visit, Cool-Grind nozzles were mounted on a couple of their machines. They were going to do their normal ops to see if the nozzles would make an improvement.

3 days had past, then Cool-Grind received a phone call from Aggressive Grinding Services to order 16 Grind-Loc kits. 12 x 1 1/2“ Multi-Jet Ultra-Wide Flat Swivel Coolant Nozzles, and 2 x 2“ Multi-Jet Ultra-Wide Flat Swivel Coolant Nozzle. After a 1 week turn around, these nozzles were in their facility ready to be mounted on the machines.

“ We have just finished installing your nozzles on our okuma Od grinders. The operators absolutely love your nozzles. We are still working on increasing our speeds and feeds. We have one job in our kellenberger department that we increased our feed rates dramatically. That job that went from a 6 minute cycle down to a 2 minute 15 second cycle on 1500 parts. Saving about 95 hours of grinding!! We are very excited to get the balance of your nozzles to install on all of our kellenberger grinders. Thanks for all your help in our continued success.” - Vice President