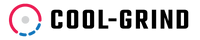

Rigid Nozzle System (formerly Nozzle Tube System)

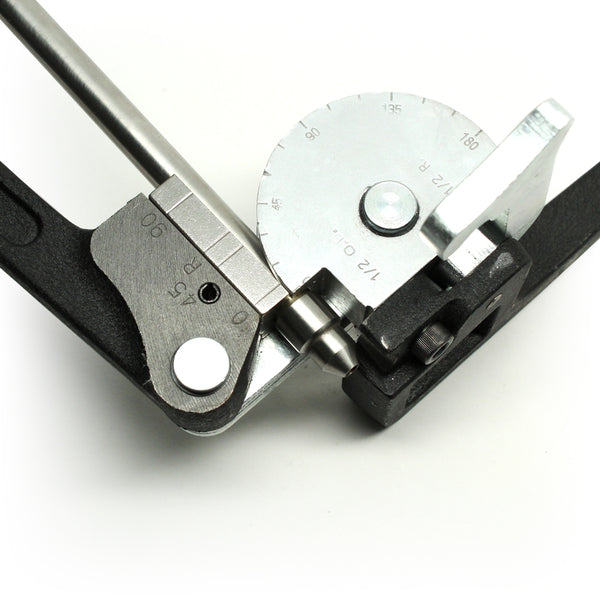

The rigid nozzle system is based on 304 stainless steel tubing of 1/2”, 3/8” and 5/16” outer diameter and includes round and flat nozzles, fixed and swivel nozzles, and axial nozzle adjustment for wheel wear comp using telescoping fittings. Flat nozzles are defined by jet width and jet thickness. Round nozzles are defined by jet diameter. Cool-Grind also supplies special tube benders that put the nozzle closer to the grinding wheel and at the correct jet angle. The difference between the Rigid nozzle System and the Grind-Loc System is pressure capability and suitability for medium to large batch production, although the Rigid Nozzle System has a lot of adjustability.