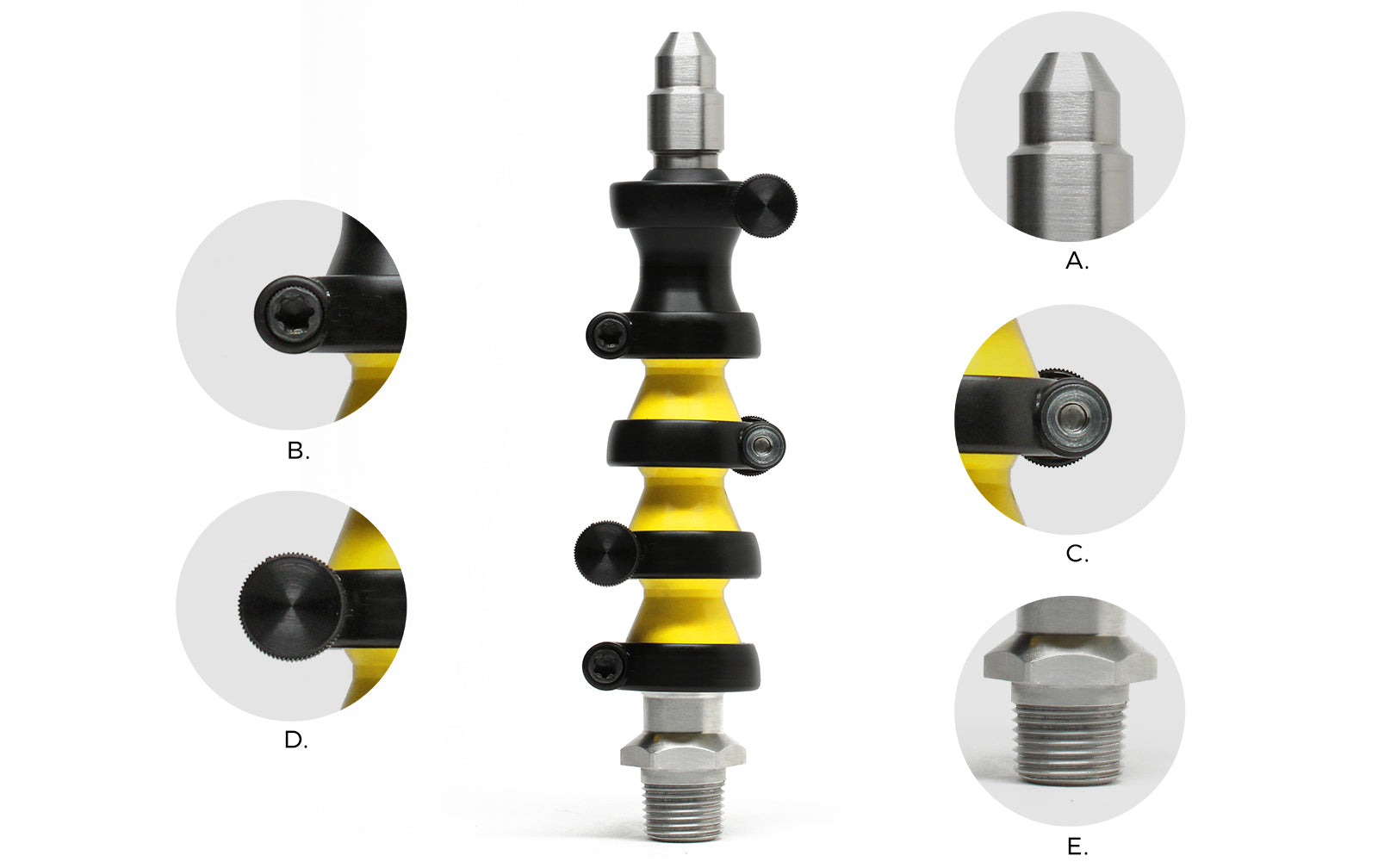

Grind-Loc Modular Hose System

Cool-Grind has critically studied the machine tool process cooling market over the last 20 years, and learned what works and what doesn't. As a result we understand that strength, versatility and fluid dynamics are key factors for an effective cooling system. Combine those factors with the precision of the pioneering Cool-Grind Technologies coherent jet nozzle geometry, and you have the Grind-Loc Modular Hose System.

A. Industry leading laser-like coherent jets. Available in round or flat.

B. Torx screw for ease of use, and prevents striping of the head. Allowing up to 100 psi.

C. Threaded open-ended metal insert, which allows for increased torque and life span.

D. Knurled knob for hand tightening. Allowing up to 50 psi, tool not required.

E. Aluminum thread and swivel ball increase strength and life span.

Save time, less scrap, and reduce cost with Grind-Loc

- You will consume far fewer grinding wheels per year.

- Greater production throughput increases your capacity.

- Improved surface finish and reduced thermal damage in the final surface.

- Greater dressing tool life and less time lost due to dressing.

- A harder grade wheel will hold form without burning the part.

If you can fit Loc-Line© you can fit Grind-Loc. This modular hose system is based on 3 different internal diameters, 1/2”, 1/4”, & 3/4" and can withstand 100psi by using external element clamps and hard plumbing. This system is based on the same ball size as Loc-Line© (fully interchangeable), uses coherent jet nozzles that swivel +/- 30 degrees, can telescope to different lengths without removing segments, and has low internal turbulence due to the class-leading generous internal diameter of the Loc-Line© components, plus the lower flowrate from the smaller coherent-jet nozzles. Standard flat nozzle jet exit apertures are 0.63″ x 0.05″ for the 1/2″ system and 0.38″ x 0.05″ for the 1/4″ system. Standard round nozzle exit diameter is 0.187″ for 1/2″ system and 0.125 for the 1/4″ system. The numbers shown after 14, 12 & 34 in the part number indicate the exit aperture.

Grind-Loc features:

- Holds its position under high pressure

- Delivers a coherent coolant jet so you get excellent heat removal without making contact with the wheel, saving nozzles

- Sets up with ease! You don’t need a big wrench, and segments you’ve secured don’t move when you adjust the adjoining segments. (If you’ve used competing systems you know what a hassle this can be!)

- Available in aluminum to eliminate the danger from sparking in oil coolant

- Interfaces with Loc-Line© components

- Comes in convenient kits for cylindrical grinding, tool grinding, and universal applications, or as sub-assemblies and individual modular components. These kits allow for the installation of up to 15 nozzle systems, and include quantities of all parts that are available individually. If certain nozzles do not suit your machines Cool-Grind will swap them with more of what you can use.